APS0552164-4

APS0552164-4

Cessna 172 Airbox Assembly

Low stock

Replaces Part Number

0552164-4 and 0552164-4AWLPMA Model Eligibility

|

If required, FAA Form 8130-3 must be added to cart. All other documents will be provided in digital format to your e-mail after check-out or provided with the shipped item. |

Couldn't load pickup availability

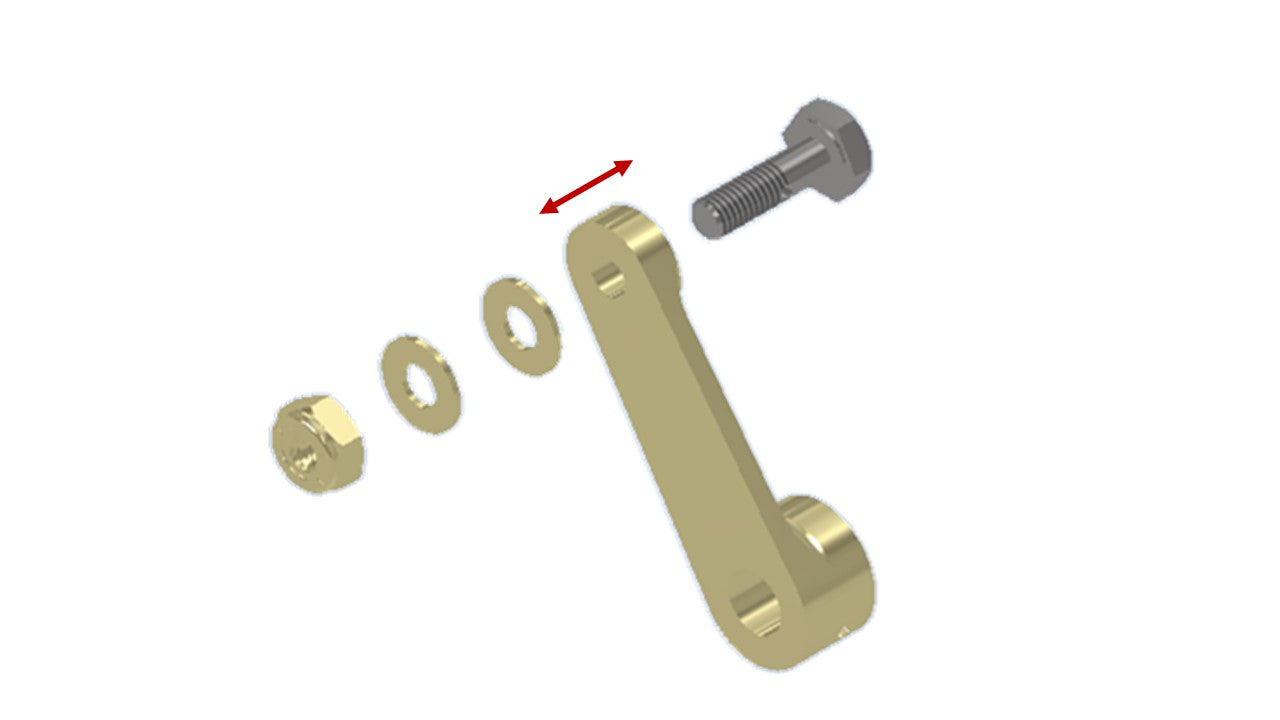

Included Hardware

- 1X - 649974 - Airbox Carburetor Gasket

- 4X – 1728902-19 - Air Filter Screws For Non-Brackett™ Filters

- 1X - APS0750111-19-1 – Carburetor Heat Cable Clamp Bolt

- 2X – AN916-10L – Carburetor Heat Cable Clamp Washers

- 1X – MS21083N3 – Carburetor Heat Cable Clamp Locknut

As the leader in firewall forward STC products for Cessna™ single aircraft Air Plains is all too familiar with customers "airbox woes". Until now customers had to choose between temporary repairing their airbox or purchasing a new airbox from Cessna™. The problem is that both options can be very expensive, and the final product is still an airbox susceptible to several common issues.

Our PMA airboxes are designed with weight in mind because we understand that a heavy airbox is a highly stressed airbox. Rather than using heavy materials such as stainless steel to replace lightweight aluminum components we have made intelligent design decisions such as better distributing loads and reinforcing riveted joints with the addition of adhesive. This improves the strength of the airbox without adding weight. The added benefit is that your aircraft does not get heavier!

The result of these improvements is an airbox superior to the factory original which will provide many more years of trouble-free service.

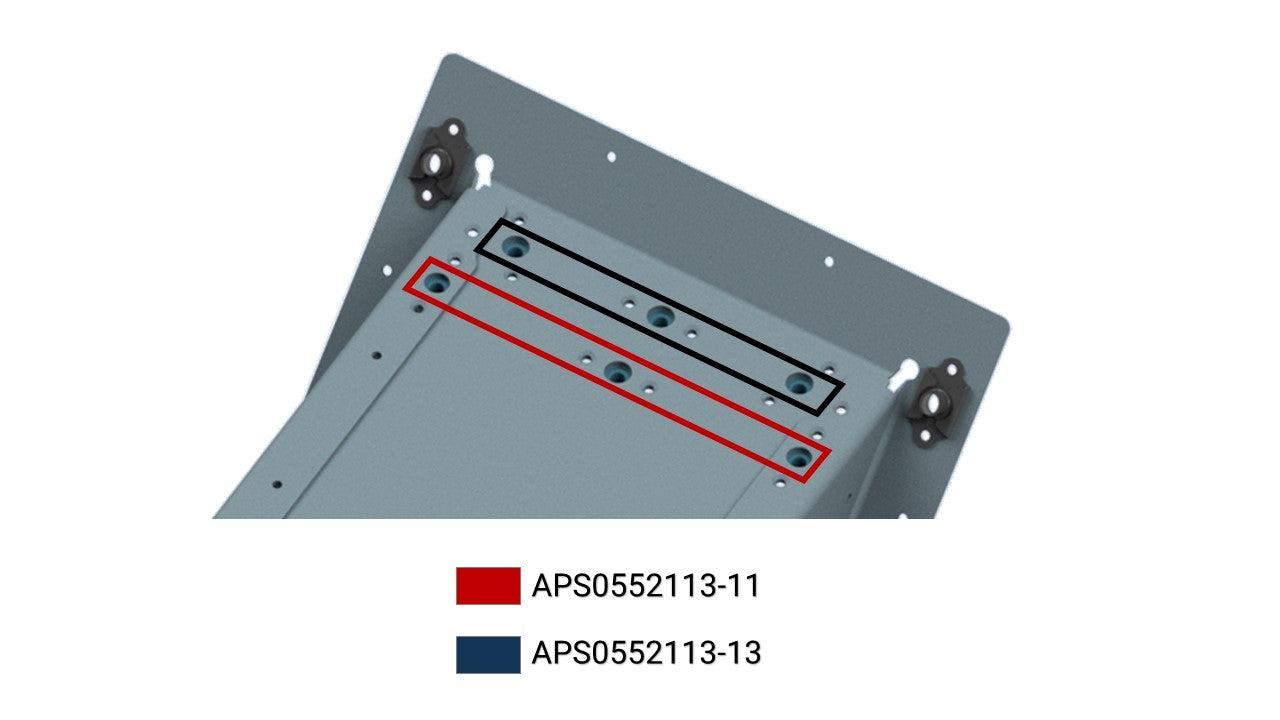

Dual Bracket Mounting Design

Our airboxes are more universal and fleet operators will love it. Both the APS0552113-11 and APS0552113-13 airboxes are identical and approved on all 172I, K, L, M, F172L, and F172M applications, this means you don’t need to keep two on hand.

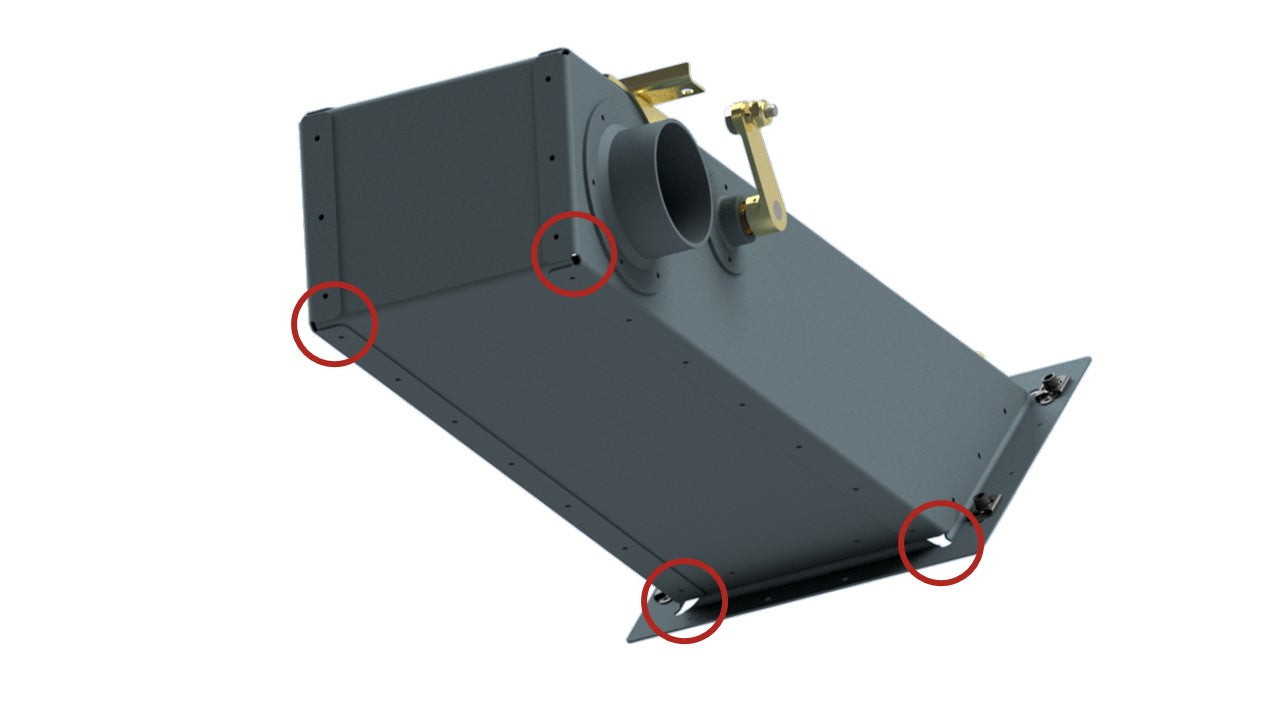

Four Corner Drain Design

The original two fuel drain holes have been replaced with four corner drains. This allows fuel drainage from any attitude on the ground, preventing airbox fires when over-primed.

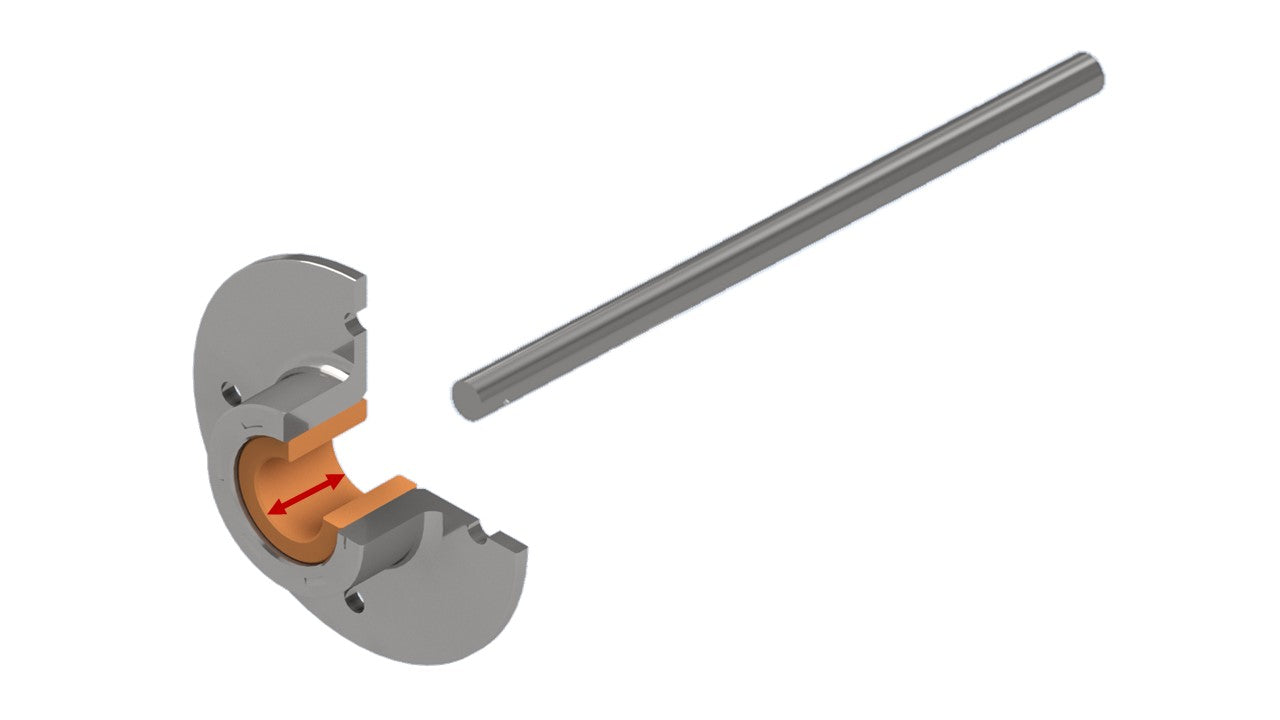

Increased Bearing Area

The shaft is made from corrosion resistant steel and the troublesome needle bearing is replaced by a more robust oil-impregnated bronze bushing which eliminates the risk of needle ingestion by the engine. The bearing area on the bronze bushing is increase to distribute the forces.

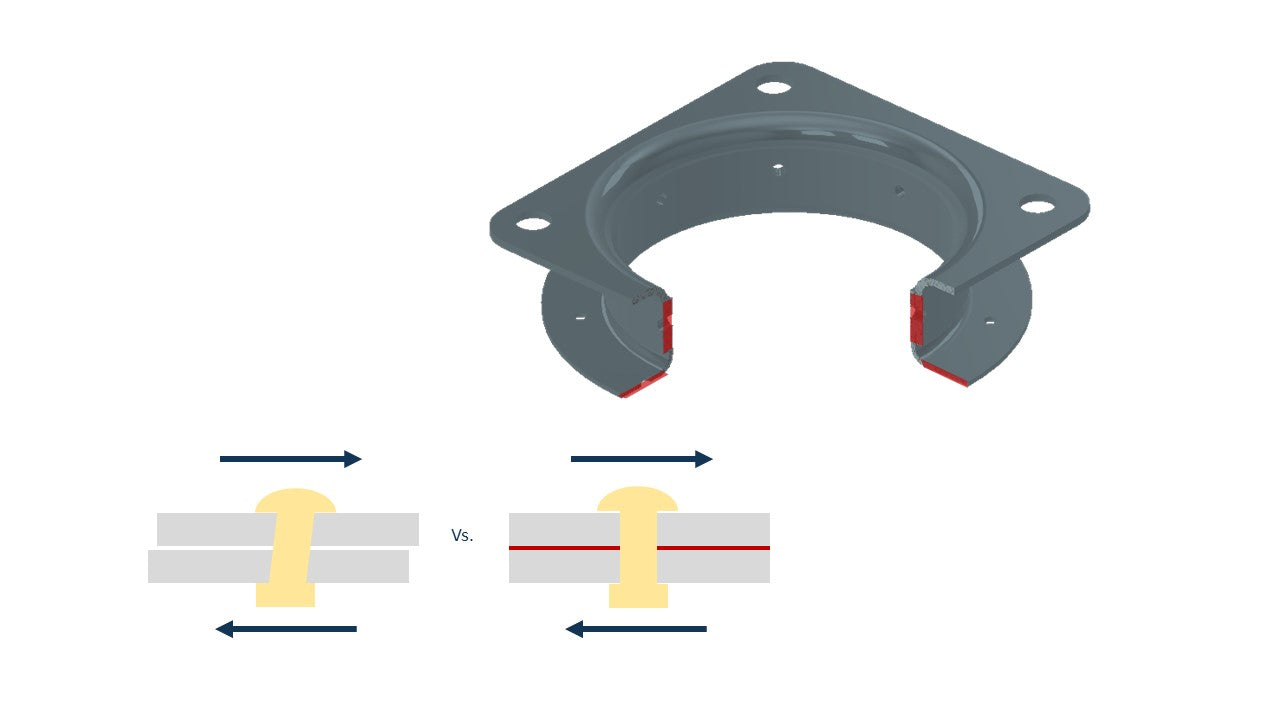

Adhesive Reinforced

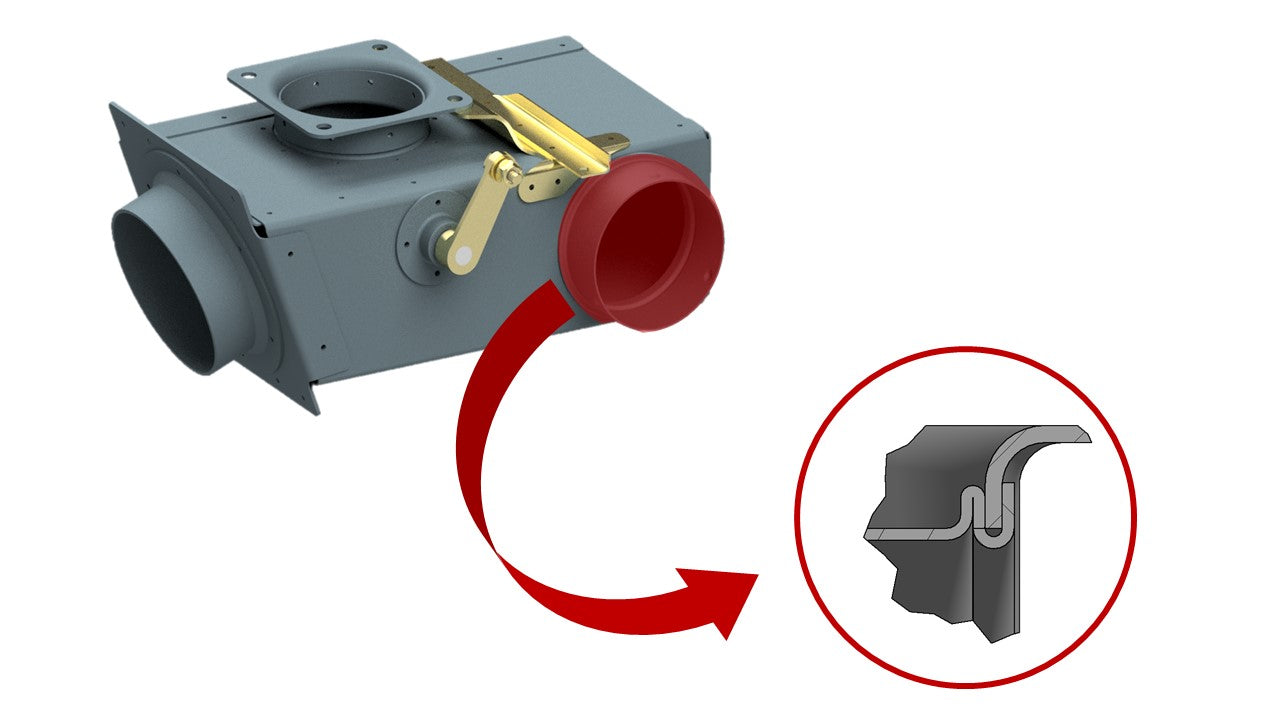

Our airbox features structural adhesive reinforcement in the highest stress areas, this distributes the stress between the skins and prevents the common cracking and collar separation issues seen all too often. The collar flange on the body is made of a stronger alloy which has been heat treated. This strengths the collar joint significantly when combined with the adhesive reinforcement.

One Piece Billet Machined Arm

This airbox also features Air Plains improved carburetor heat arm which is manufactured from hardened steel and has a larger bearing area for the clamp; this significantly reduces the wear from the cable clamp.

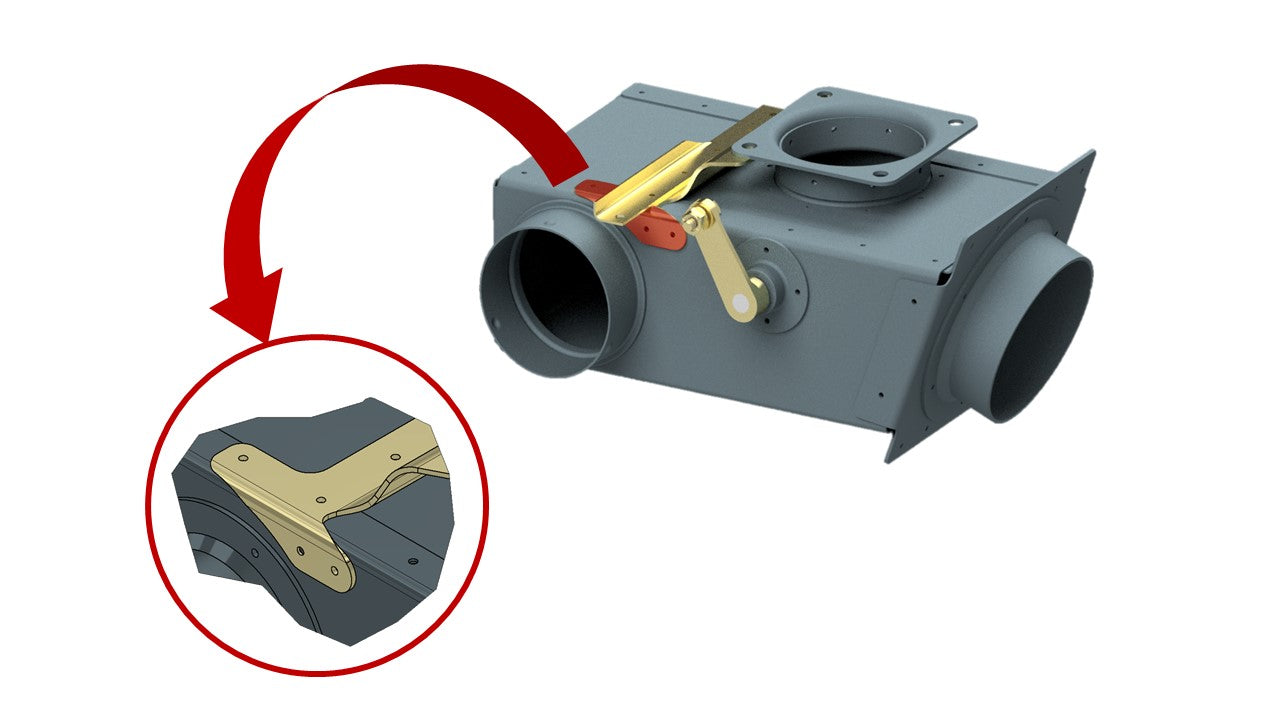

Steel Bracket Reinforcement

Because we know where are all the weak areas on the airbox we applied some out of the box thinking. The steel bracket used for the carb heat cable has been redesigned to prevent cracking of the co-pilot side skin below it. This provides a better distributed load from the bracket.

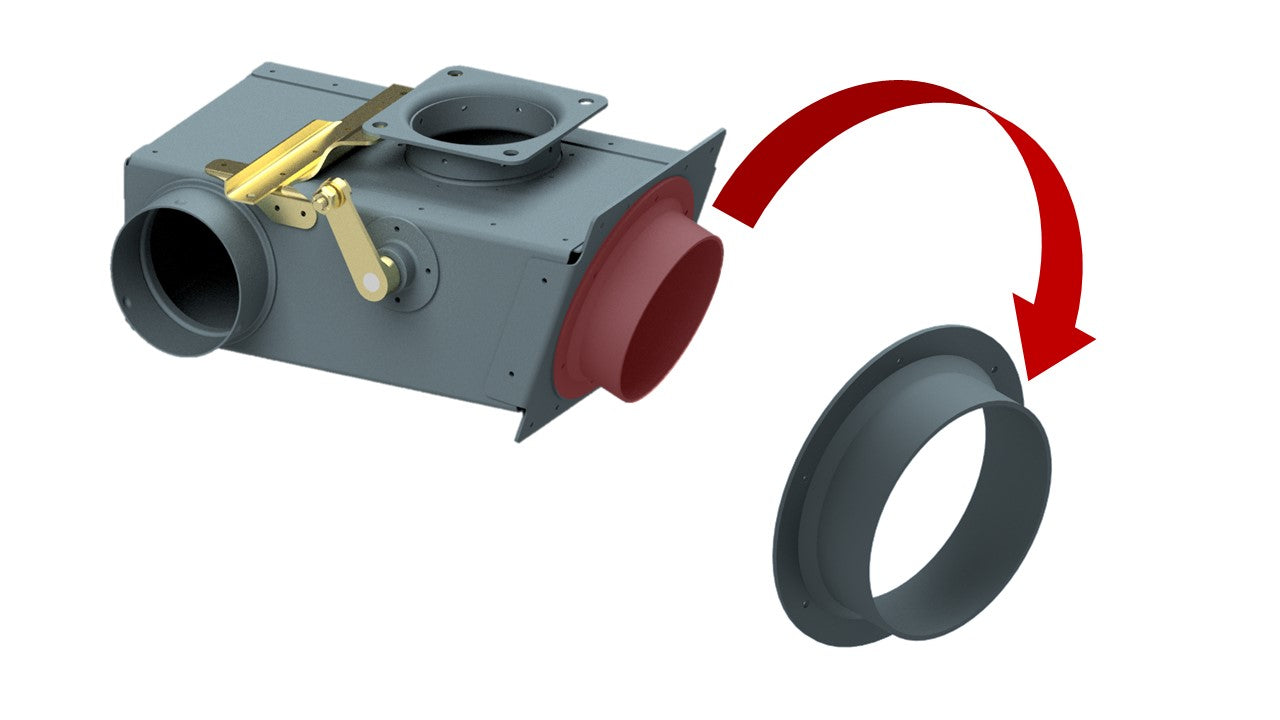

Welded Flange

Our thicker welded flange is welded and rivet on the airbox. This improves the structural integrity of the airbox against any failure.

Stronger Crimp and Bonded Duct

Our airbox features structural adhesive reinforcement in the highest stress areas, this distributes the stress between the skins and prevents the common cracking and collar separation issues seen all too often.

It is important that your carburetor airbox rigging is set correctly. There should be a cushion gap of 1/16 of an inch between the cable knob and panel stop. If the gap is too small the valve assembly will rattle due to vibration and air loads.